Back Out & Relief Cuts Moulding Catalog

A backout/relief cut is a shallow dado milled on the backside of wood moldings to help prevent cupping and warping. It can relieve any stress in milled lumber that may be case hardened due to improper drying techniques and allow airflow between surfaces while providing a good transition between framing and sheetrock when installed. A common practice is one-sixteenth to one-eighth of an inch in height for each three-quarter to one inch of thickness of milled wood. We prefer to use 45-degree angles in the transition areas. It will be easier to sharpen the knives when needed. The cutters will also benefit from longer milling times than backout/relief cut designs with transitions of greater angles. We have over two hundred styles of backout and relief cuts for door & window casings, baseboards, tongue & groove flooring, and door jambs. Backout knives are the most neglected cutters on the machinery. Inexperienced operators don't realize the finish problems dull knives can create from the abandonment of sharpening. When troubleshooting equipment problems, I always hear that "it's just a backout cutter." Listen to the machine; if your moulder is excessively loud or you're experiencing finish problems that look like chatter. The molder is begging you to sharpen the relief cut knives. You will experience intermittent indentations at the top of the profile while milling. What's happing is the blades are so dull that the lumber lifts off the bottom bedplates momentarily, walking over the knives instead of cutting thru the wood, creating finishing issues on the top of the lumber because of the proximity of both cutterheads. When searching for relief cut designs, please input width dimensions to narrow size preferences in the above search boxes, either a fraction of an inch or decimals. If you want a specific size backout, enter the minimum and maximum dimensions. If by chance you don't find a relief cut that works for your current application, just send us a sketch. We will design a new backout profile on cad, cut an acrylic template on our CNC machinery, and grind a set of cutters on our Weinig R 960 grinder, in any high-quality knife steel we offer.

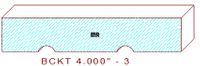

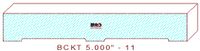

Template Ready

Downloadable DXF File

click to view full scale & pricing options

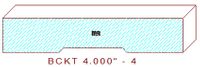

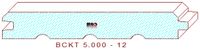

Template Ready

Downloadable DXF File

click to view full scale & pricing options

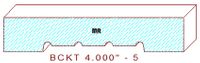

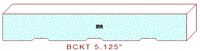

Template Ready

Downloadable DXF File

click to view full scale & pricing options

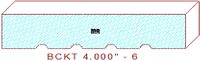

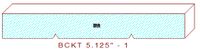

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options

Template Ready

Downloadable DXF File

click to view full scale & pricing options