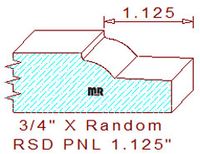

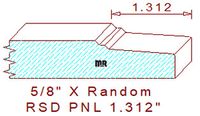

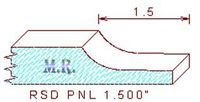

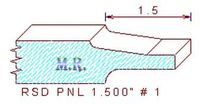

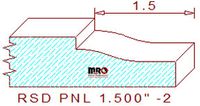

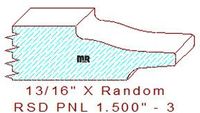

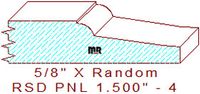

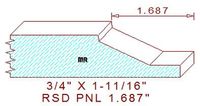

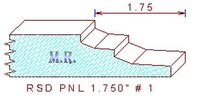

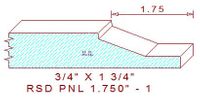

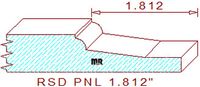

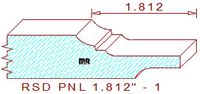

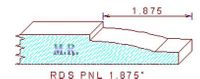

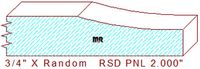

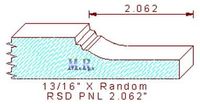

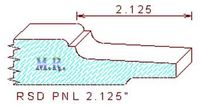

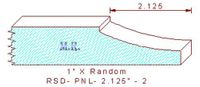

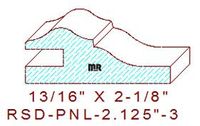

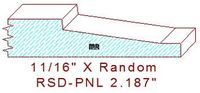

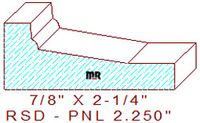

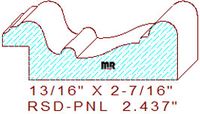

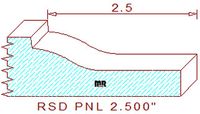

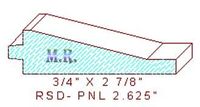

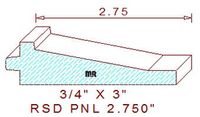

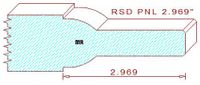

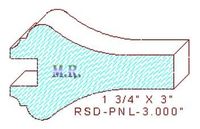

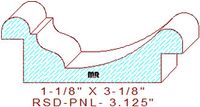

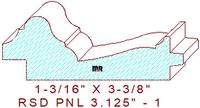

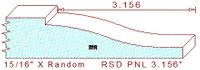

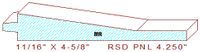

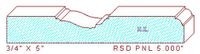

Raised Panel Moulding Catalog

After the milling process, on a shaper, the panels are inserted into grooves in the vertical and horizontal members of a stile and rail, cope and stick, or mitered door rail and drawer front type of frame. In this style of door construction, the panel will generally float within the frame so it can easily adjust to seasonal changes in relative humidity without damaging the structure; using space balls in the grooves during assembly is the preferred method of building a raised panel.

If by chance you don't find a profile that best fits your application, send us a sketch. We would be happy to design a new profile on CAD, cut an acrylic template on our CNC machinery, and grind a set of cutters on our Weinig R 960 profile grinder for any pattern you desire. Don't forget; we have an easy-to-use profile knife calculator located directly under every detail in our catalog, offering immediate, accurate price quotes.