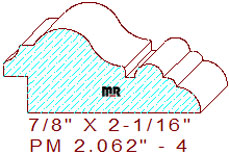

Panel Moulding 2-1/16" - 4

Panel Moulding 2-1/16" - 4

Proper tool balance is incredibly significant to your current molding operation. Read how critical it is to have balanced knives, screws, gibs in the cutter head. The is also information on the problems it can create if you neglect to focus on this simple task. Protect your current investment of woodworking machinery; your clients will appreciate the quality of the wood molding and your disciplined approach in manufacturing.

Caution: the cutters will come within .020" of the machine bed plates when milling this detail. We recommend a wooden, phenolic, or plastic sacrificial bed plate for these types of milling operations. For molding knife quoting purposes click to open the calculator below, we supplied only the important measurements, enter the appropriate dimension in the boxes provided. A brief detailed explanation on how to use the calculator is located here. If you would like some assistance with the dimensions print a copy of our fraction - decimal - millimeter chart, place it on the molder, or around the shop to help machine operators save time and increase accuracy during setup procedures.

Width = 2.062" / Depth of Cut = .875" (top knives).

Thickness = .875" / Depth of Cut = .250" (left cutters).

Note: If you’re experiencing trouble printing to Full Scale, Go to File, Print Preview. Change the “Shrink to Fit” option to 100%