This article will provide some safety tips, suggestions, causes and

solutions on how to by-pass moulding knife damage or breakage on

industrial moulder's while milling lumber.

Industrial molding knife damage occurs daily in our industry, it is an

unfortunate situation, but is more common than one would think, this

phenomenon will eventually materialize with all machine operators

throughout their careers.

Everyone's concern is the safety of the machine operator and others

around the milling operation; this reiterates the obligation that all

cutterhead guards, hoods, and other safety devices should always be in

there proper place and functioning throughout the service life of the

machinery.

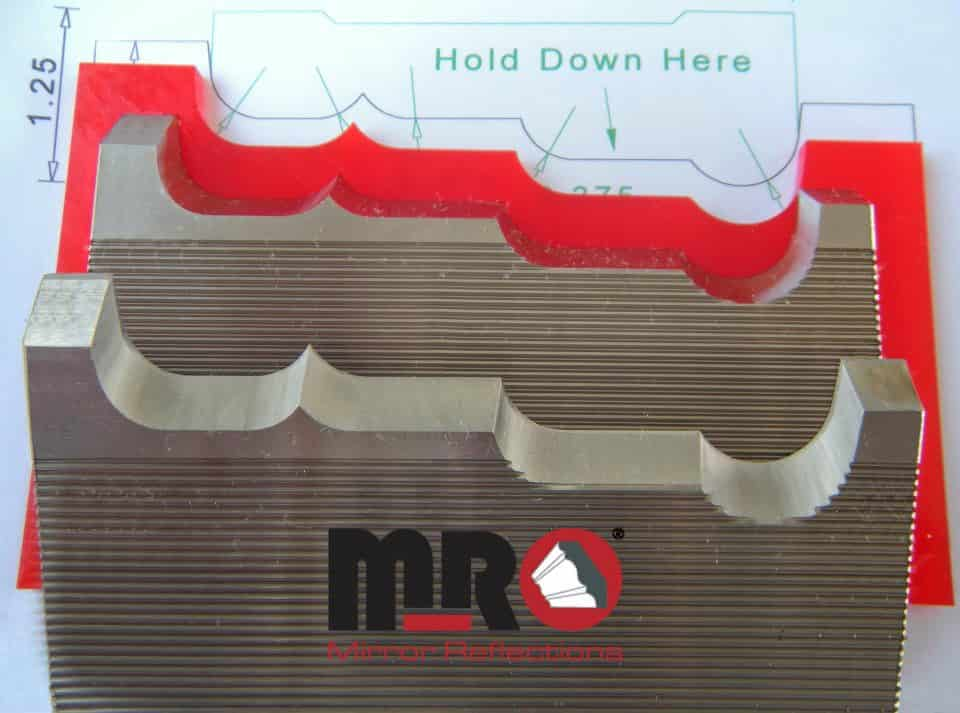

Below are a couple of images of damaged knives we received for

sharpening. On the first pic, look where the pencil is pointing, it is

obvious these blades lightly struck one of two areas on the moulder,

either they came in contact with the left adjustable guide fence (most

likely), or the machines bedplates. What's notable is, we had the

knives designed the exact opposite before these cutters were

signed off, and manufactured, but

the business owner insisted we mill the thin portion of the profile

closest to the left outside edge on the machinery. We explained that

the blades could easily be damaged while milling, Mirror Reflections

has

designed and manufactured moulding knives

for over thirty years, but some people have no interest in useful information,

sometimes you cannot save people from themselves luckily no one got injured.

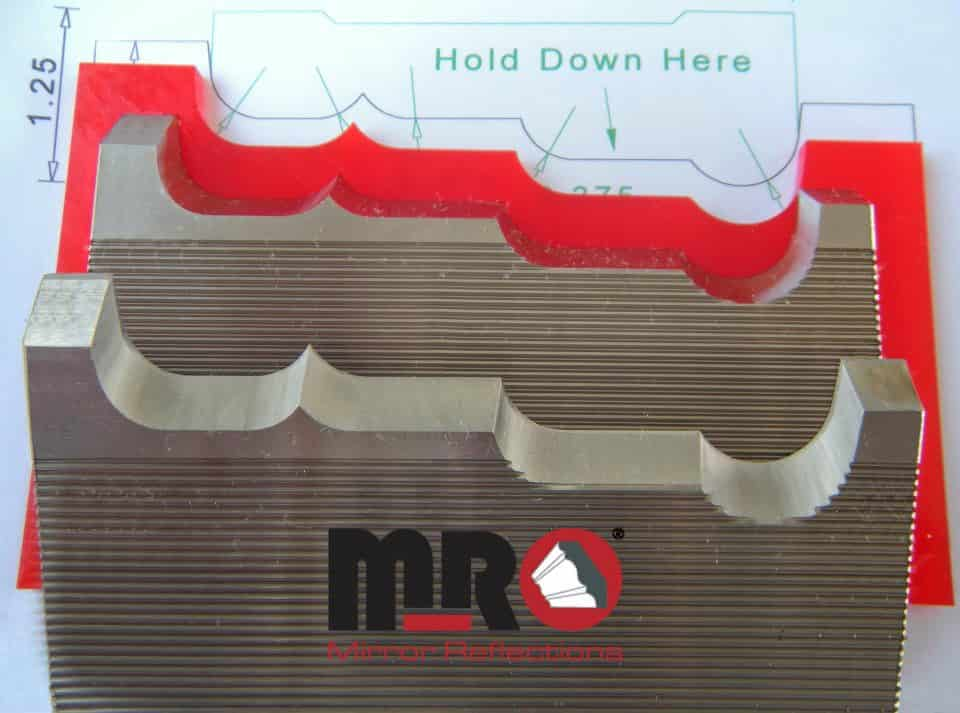

In the crown knives image, the blades struck multiple foreign objects

buried in the lumber, or end grain of the wood while milling. We will

refrain from speculating on how these knives were broken, in some

cases we just do not know.

We have compiled a list below of possible causes and solutions of

items that might contribute to possible knife fracture and breakage.

Your safety and health are our primary concern, it is your duty and

responsibility to abide by all safety practices set forth by your

employer and the manufacturer of your machinery.

Cause:

Moulding knives encountered

the bedplates, chip breakers, guide, or stationary fences while in operation.

Solution:

Rotate moulding knives

slowly by hand in reverse of normal rotation during setup. This procedure

will confirm cutters will clear all obstacles they may encounter during

milling. Perform a crash test on all chip breakers, chip deflectors,

and pressure elements with a 2x4 during set up, adjust cutting circle

if necessary. Proper knife design is essential in all profiles for this

to be problem free.

Cause:

Knots in the lumber may dislodge

while milling, they became projectiles striking the blade, which causes

fracturing, and or breakage.

Solution:

Possessing a small rubber

or hard plastic mallet would allow the machine operator to lightly tap

the knot or knots to assure oneself that these knots in the lumber would

proceed thru moulder and remain intact throughout the process.

Cause:

Moulder operator halted the

cutter head spindle motors prior to the machine’s feed system. Motor

spindle brakes stop the cutterhead spindles very quickly, if motor spindle

brakes activate while the feed system is in operation it could be the

origin of knife breakage, some newer models of moulder’s have safety

limits in place to avoid this action from occurring.

Solution:

Incorporate systematical

procedures for starting and stopping of the cutterhead spindles and feed

systems, all machine operators are required to obtain extensive training

in these guidelines.

Cause:

Machine operator neglected

to remove the lash or slop in the adjusting screw threaded rod on moulding

cutterheads during set up procedures. The probability exists that when

running a profile where the knives are close to the bedplates while operating,

slop or lash in top spindle adjusting screw threads will allow the knives

to encounter bedplates resulting in breakage of the cutters.

Solution:

While setting up moulder,

all final movements of moulder spindles should be toward the lumber except

the top spindles, this action will assure the operator that all lash

in adjusting screw threads was eliminated, it is commonly referred to

as the loop on CNC spindles. On the top horizontal spindle, set knives

horizontally during set up, this procedure will eliminate the possibility

of the knives encountering the bedplates or guide fences when removing

lash from top spindle adjusting screw.

Cause:

Moulder operator started moulding

machine with woodwork piece already in moulder, overlooking manual hand

spinning heads in reverse of normal rotation prior to exclude any tension

that might occur on work piece before starting.

Solution:

If the moulder was shut

down with lumber still in machine, while in the off position, manually

release spindle brakes if applicable, check spindle rotation by hand,

in reverse of normal rotation to assure cutter head is capable to spin

freely when spindle motor is activated.

Cause:

The operator placed the machine

under full workload before the machine had a chance to reach full rpm’s

causing excessive stress on knives, even breakage.

Solution:

Most new style moulders

that utilize flat belts on spindles and motor pulleys have soft start

motors. Soft start is a two-stage start up procedure to achieve full

rpms and keep the belts from burning or breaking during startup. Soft

start motor stages are controlled by timers in the electrical cabinet,

give the moulder about 15-20 seconds after starting, this time allows

for the second timer to engage giving full rpm’s power to the motor,

eliminating the opportunity for moulding knife breakage.

Cause:

Improper machine set up techniques;

fences, chip breakers, and guides tightly adjusted, feed system not properly

fine-tuned for thickness of lumber, this causes feeding issues. Whacking

the ends of boards against one another to get the lumber to advance through

moulder feed system will increase probability of breaking the knives

quickly.

Solution:

A firm setup is fine,

the tighter the setup the more friction and increased pressure on the

feed system, the feed system should be set at the finish thickness size.

Proper training will eliminate most feeding problems for moulding machine

operators.

Cause:

Improper cooling of the high

speed knife steel after cutting, and while grinding can cause fracturing

of the tool leading to breaking upon using the knives please refer to

our article on

aligning moulder knives in the cutterhead.

Solution:

Do not submerge knives

in cold water after cutting to length; let the knife blanks cool at room

temperature, the sudden change can cause the knife to fracture without

you even realizing it. Use enough coolant from the face (smooth side)

of the knife while profile grinding. Burn marks on the face side of the

knife steel indicate burning of the tool, this makes the blade fragile,

the brittle the knife steel, the easier it is to break.

Cause:

Dull knives, the spindle motor

will generally always force the blades to cut, but if the knife is dull

it will build up heat, initiate finish issues, and eventually fracture

leading to machine damage.

Solution:

This is an easy fix;

keep your moulding knives sharp!

Cause:

Improper steel size, we always

supply you with the correct steel height sizes on all our profile cad

drawings, if you routinely use a bigger size steel to make it last longer,

you are only increasing the size of your cutting circle, this can lead

to knife breakage from unsupported lumber while machining.

We have provided you with some especially important information about

high speed steel and carbide cutters, and some reasons for failure

during manufacturing and milling of lumber. Although we may not have

covered all the reasons for knife failure, these solutions will solve

many issues. A highly skilled, experienced machine operator with

formal training can significantly reduce the possibility of the

concerns expressed in this article. We also recommend reading our

article on

production tips

for moulder operators for moulder operators to eliminate concerns not discussed

in this article. If we can be of any further support, please,

contact us

.