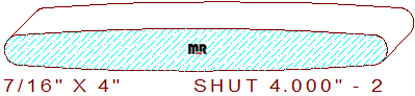

Shutter/Louver 4" - 2

Shutter/Louver 4" - 2

Some louver manufacturers mill these profiles on the top and bottom horizontal cutterheads. Our concern with this machining approach is that you have ninety-degree cuts where the top and bottom cutters cross each side edge of the design. This practice leads to the burning of the knives, decreasing production times between sharpening. This area is also where one eye will be when the open window covering is horizontal. Larger cutting circles on the machinery will force you to open bedplates and chip breakers while simultaneously causing snipes on the finished products. Trust us; four milling stations are the correct way to mill louver slats. It will cost more money on tooling and more time to set up the machinery, but you will have far less machining trouble in the long run, and your product will be superior to those mills doing it the less expensive way.

For knife quoting purposes use the calculator below; we have added only the important measurements. A brief detailed explanation of how to use the calculator is located here.

Width = 4.000" / Depth of Cut = .095" (top knives) & .095" (bottom cutters).

Thickness = 1.625" / Depth of Cut = .274" (right blades) & .274" (left cutters).

Note: If you’re experiencing trouble printing to Full Scale, Go to File, Print Preview. Change the “Shrink to Fit” option to 100%