Ever notice why some moldings look better than other trim patterns in homes, offices, and older buildings. You may want to review our article on knife marks per inch. Read about how machine feed rates and rpm of cutter heads can directly determine the quality of the products you produce. Following or exceeding industry standards will allow your company to lead the way in molding artisanship.

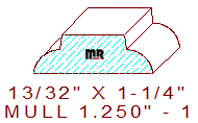

Caution: the cutters will come within .020" of the machine bed plates when milling this detail. We recommend a wooden, phenolic, or plastic sacrificial bed plate for these types of milling operations. For molding knife quoting purposes, click to open the calculator below; we supplied only the important measurements, enter the appropriate dimension in the boxes provided. A brief detailed explanation on how to use the calculator is located here. If you would like some assistance with the dimensions, print a copy of our fraction - decimal - millimeter chart, place it on the molder or around the shop to help machine operators save time and increase accuracy during setup procedures.

Width = 1.250" / Depth of Cut = .406" (top knives).

Note: If you’re experiencing trouble printing to Full Scale, Go to File, Print Preview. Change the “Shrink to Fit” option to 100%

1588 South 250 East | Kaysville, Utah 84037

Phone/Fax: 801-451-5987

Moulding Catalog Updated Saturday, April 19, 2025

© Copyright 1997 - 2025 Mirror Reflections Inc. All Rights Reserved.